Research Progress in the US – The Flexible Electronics Market Burst out

How many sensors are there on our body to make us feel healthy? To answer this question, you must know about the flexible hybrid electronics - a unique industrial technology research direction.Flexible hybrid electronics (FHE) is considered as the future of the electronics industry and it has become an important research topic for the government of the United States (US) due to its wearability, bendability and stretchability. In particular, the US military invested heavily in the development of flexible electronics, which shows the strategic significance of this technology in the future.

清華(huá)大學(xué)航天航空學院(yuàn)的馮雪教授和浙江(jiāng)大學化學工程與(yǔ)生物工程學院的謝濤教(jiāo)授團隊合作,In August 2015, the 7th manufacturing innovation institute in the US - Flexible Hybrid Electronics Manufacturing Innovation Institute, was established in the Silicon Valley. This institute is led by the Department of Defense with a total investment of US$171M, of which US$75 million comes from federal funding and US$96 million is non-federal funding. The FlexTech Alliance will lead 96 companies, 41 universities, a group of 14 state and local government organizations, 11 laboratories, and non-for-profit organizations to ensure the US is leading the next generation of flexible and wearable electronic device manufacturing. This group consists of the main American electronics and semiconductor companies such as the applied materials companies, Apple and the United Technologies Corporation as well as leading research institutes like Stanford University, Harvard University and Massachusetts Institute of Technology. The new institute will focus on the leading research of flexible hybrid electronics production to form wearable and stretchable silicon circuits and sensors via high-performance appliances and printing technologies.Applications of FHE include the following:

1.monitor vital signs and physical status through wearable electronic information devices to optimize health and lifestyle decisions;

2.significantly improve the delivery of medical technologies through biomarkers and implants to monitor the vital signs of patients with chronic diseases and combat soldiers;

3.monitor the operating status of car and airplane under severe weather conditions through the embedded sensor;

4.enhance the security of military operations by applying lightweight robots and next-generation imaging and sensor capabilities to a variety of land-based, sea-based, space-based, and space-based systems;

5.significantly reduce the size and weight of electronic system modules by fitting them into the shape of aircraft and other vehicle platforms, or by integrating them into clothing and fabrics.NextFlex is worth of paying attention to among the American innovation institutes, as its research directions and industrial applications are highly related to everyone’s daily life, which includes the wearable applications of health monitoring devices, the sensor of the Internet of Things, and the integrated application of array antenna. Big technologies firms such as Huawei and Xiaomi are paying close attention to the smart wear technologies such as smart wristbands as it is a fast-growing industry. Of course, the sort of smart watch you are using now is nothing compared to NextFlex. NextFlex demonstrates enormous market value and a bright future.The flexible sword

You need to learn about Flexible Hybrid Electronics (FHE) before understanding how NextFlex works. Quite different from the traditional chemical etching methods, FHE creates printed circuit boards on flexible materials to realize folding and flexible bending for electronic equipment. ,該方(fāng)法(fǎ)預先編程控製襯底的剛度,得到剛性區域與(yǔ)柔性區域相間分布的襯底,然後直接(jiē)在襯底表麵進行薄膜沉積與光刻等操作(zuò)。其中(zhōng),功(gōng)能微單元位於剛性區域,在應變隔離的環境中穩定工作,而柔性區域則負責連接各功能微單元,使器(qì)件整體柔(róu)性可拉伸。

剛度可編程襯底(dǐ)

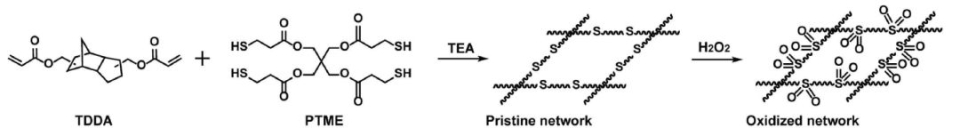

該功能襯底為通過硫醇-丙烯酸酯點擊化學反應合成的聚硫化合(hé)物薄膜,被過氧化氫氧化後轉變為聚碸化合物。為了實現特定區域的氧化,研究者使用圖形化的無塵紙作為載體吸收過氧化氫水溶液(30%)覆蓋於薄膜表麵來完(wán)成氧化,區域氧化後薄膜的(de)彈性模量提高了150倍。

材料的合成

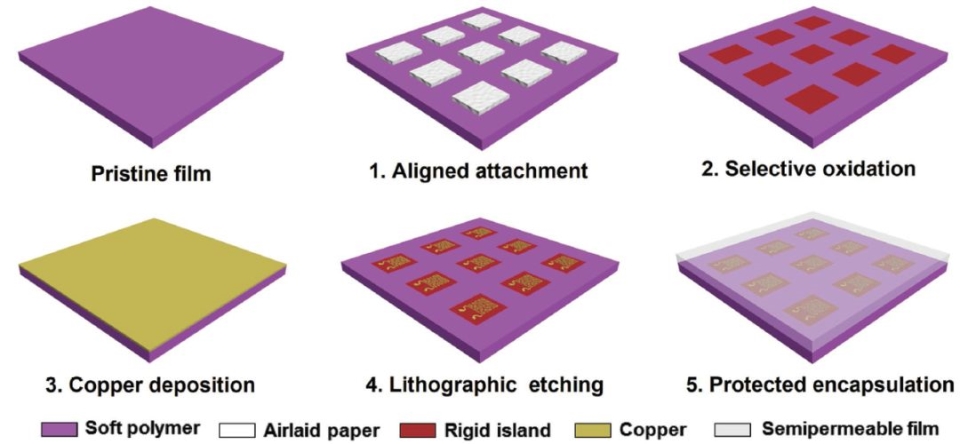

基於剛度可編程(chéng)襯底的柔性電(diàn)子器件(jiàn)製備流程

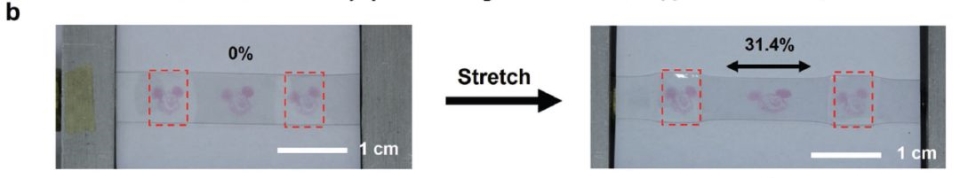

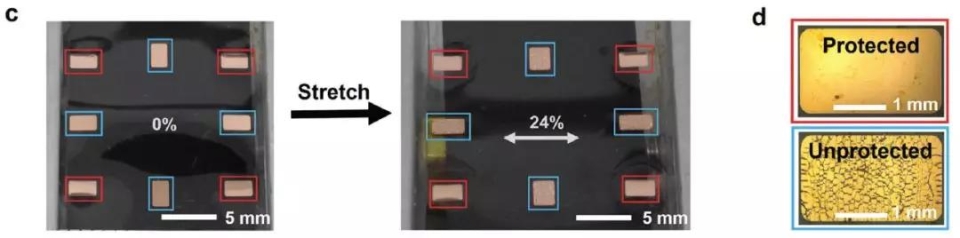

襯底在經受拉伸時,由於彈(dàn)性模量(liàng)的巨大差別,未氧化區域即柔性區(qū)域被拉伸,而被氧化的部分即剛(gāng)性區域的應變則幾乎為0。

圖b 印有米(mǐ)奇圖案的(de)剛(gāng)度編程襯底拉伸前後對比(bǐ) 圖c, d 沉積金屬薄膜的剛(gāng)度編(biān)程(chéng)襯底拉伸前後對比

圖b 印有米(mǐ)奇圖案的(de)剛(gāng)度編程襯底拉伸前後對比(bǐ) 圖c, d 沉積金屬薄膜的剛(gāng)度編(biān)程(chéng)襯底拉伸前後對比

高性能可拉伸溫度傳(chuán)感器

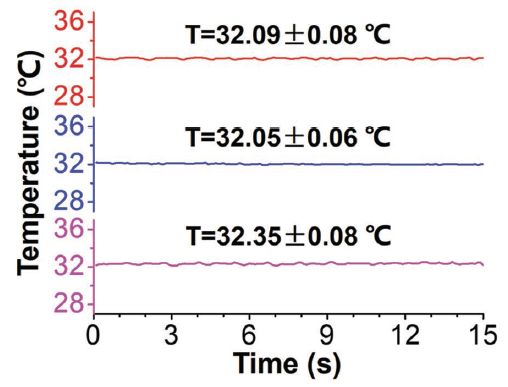

金屬電阻式溫度傳感器具有精度高、響應快、分辨率高等優點,但(dàn)對於柔性可拉伸溫度(dù)傳感器,應變同(tóng)樣會引(yǐn)起電阻的相對變化,進而(ér)影響溫度測量的結果。利用基於剛度(dù)可(kě)編程襯底的(de)柔(róu)性電子製造方法,可以將應變敏感的溫度傳感微單元布置於剛性區域,從而完美解決(jué)熱阻效應與(yǔ)壓阻效應耦合的難題。

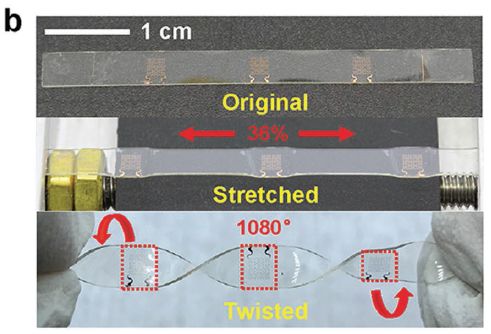

圖b 可拉伸(shēn)溫度傳感器陣列

研究者們展示了可拉伸溫度(dù)傳感陣列在動態力學環境下的測溫實驗,實時監測手腕關節與膝關節在持續運動(dòng)狀態下的溫度。

手腕運動狀態下溫度的(de)實時測量

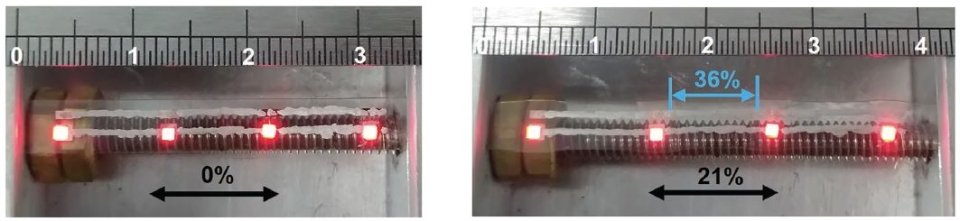

此外,研究者們還展示了柔性可拉伸LED燈鏈,減薄的(de)LED芯片(15μm)位於剛性區域,當器件承受拉伸時,柔性區(qū)域的導電銀膠(jiāo)導線隨之變形。

柔性LED燈鏈拉伸前後的對比

柔性LED燈鏈拉伸前後的對比

基於剛度可編程襯底(dǐ)的製造(zào)方法與現有光刻製備工藝兼容,製備過程無需轉印,極大降低了柔性電子器件製造的複雜度,是一種適用於柔性電子商業化生產的有效方法。

參(cān)考文(wén)獻:

Y. Cao, G. Zhang, Y. Zhang, M. Yue, Y. Chen, S. Cai, T. Xie, X. Feng, Adv. Funct. Mater. 2018, 1804604.